Generally, the theoretical basis of the piston rod design of the reciprocating compressor is to operate in a clean gas source, and then according to the compression medium and operating conditions, the corresponding raw material selection and process processing. However, when the corrosive gas is contained, the surface of the piston rod is extremely damaged, which seriously affects the gas quality, that is, the service life of the piston rod.

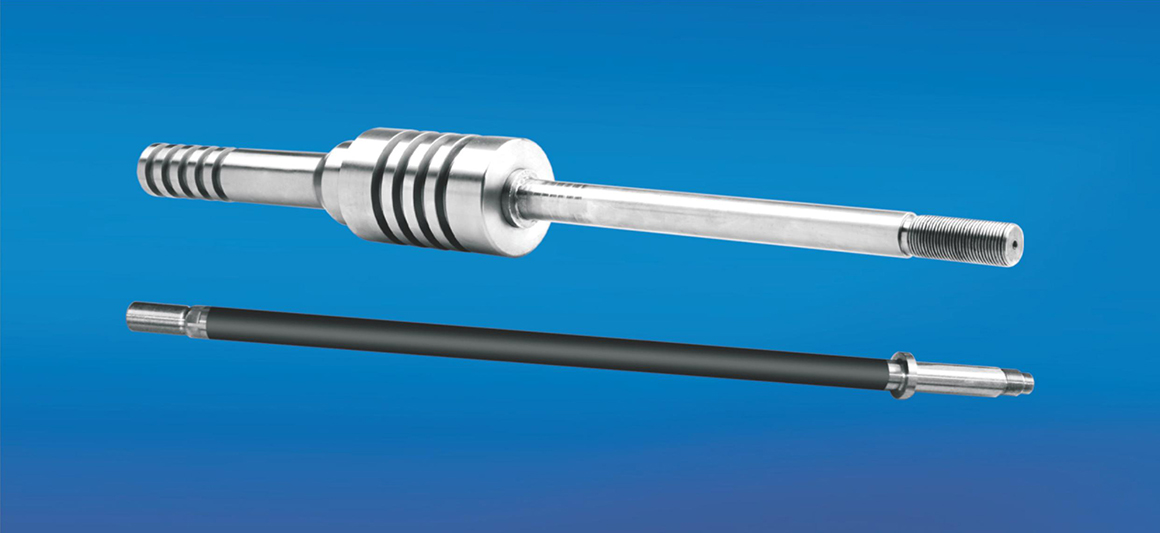

For the above industrial and mining, our company has successfully developed coated piston rods. The utility model is characterized in that the surface of the piston rod is provided with a coating, and the coating adopts a supersonic thermal painting process, and has the characteristics of abrasion resistance, corrosion resistance, high temperature resistance, high pressure resistance and oxidation resistance. The piston rod is more than three times longer than conventional piston rods, so the product is becoming more and more widely used.

For the above industrial and mining, our company has successfully developed coated piston rods. The utility model is characterized in that the surface of the piston rod is provided with a coating, and the coating adopts a supersonic thermal painting process, and has the characteristics of abrasion resistance, corrosion resistance, high temperature resistance, high pressure resistance and oxidation resistance. The piston rod is more than three times longer than conventional piston rods, so the product is becoming more and more widely used.

Introduction to coating technology:

Bond strength≥10000PSi

Porosity below 1%

Coated Vickers hardness between HV1000-HV1350(Rockwell hardness is the conversion hardness)

High pressure(70Mpa - 140Mpa)

Wear-resistant, erosion-resistant, corrosion-resistant (salt corrosion, acid corrosion, alkali corrosion, hydrogen sulfide corrosion, etc.)

The coating material is made of American praxair TAFA, American Stellte, German H, C, Starck materials, etc., and the coating materials can meet the requirements of various harsh working conditions.